01

Spinning Step by Step Processing Forming

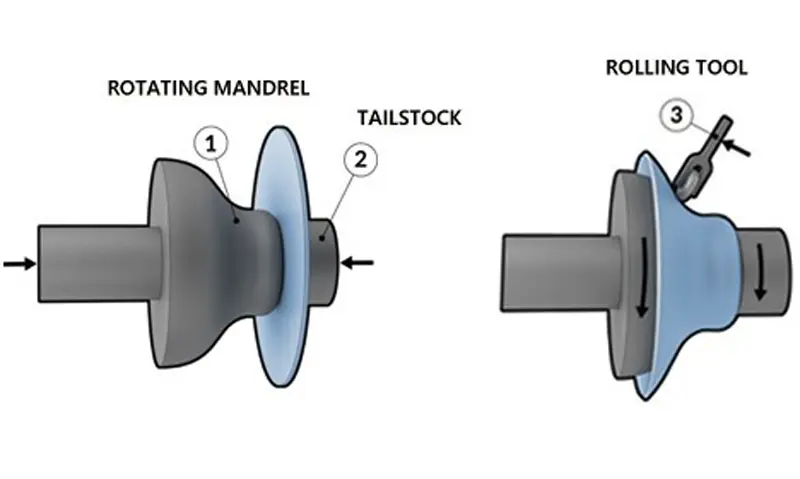

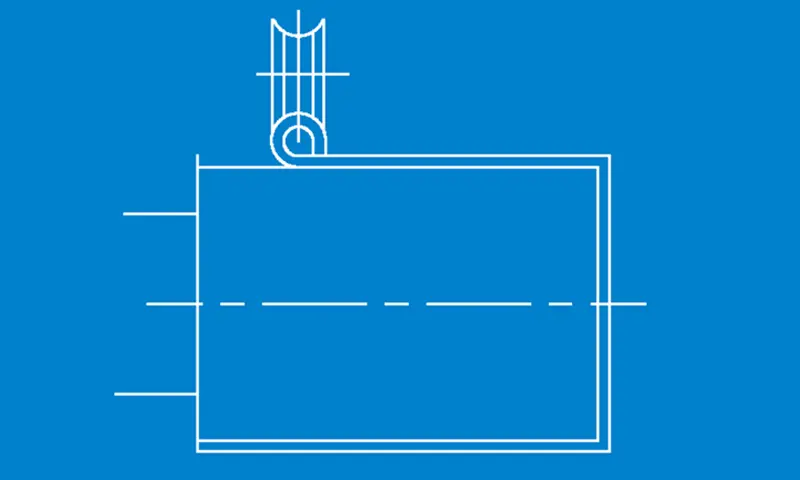

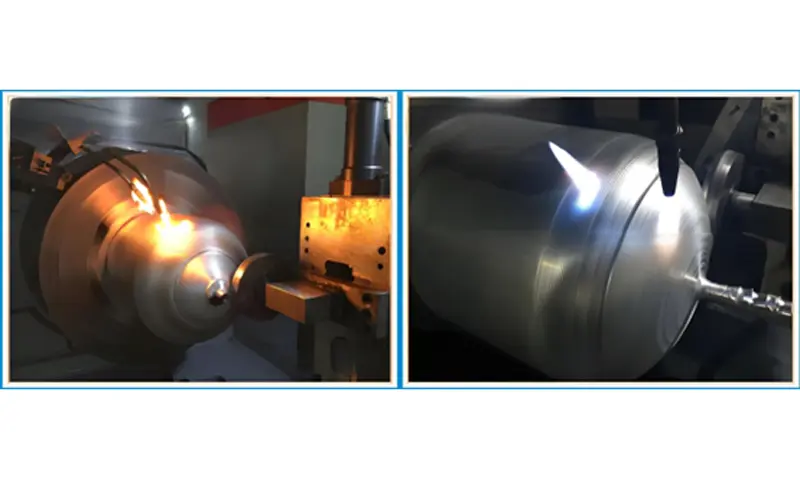

When using the spinning process, firmly fix the circular billet between the spinning machine core mold and the tail top. The key point is that the internal shape of the spinning machine core mold matches that of the workpiece, and the spindle drives the billet to rotate.

Controlled extrusion force is applied to the blank from both the longitudinal and axial directions by the rotary wheel, gradually squeezing the material onto the core mold. At the same time, the rotary wheel alternately moves back and forth in a curved motion towards the edge of the blank, and the final finishing motion achieves the expected size and surface quality of the workpiece.

01

The principle of spinning process

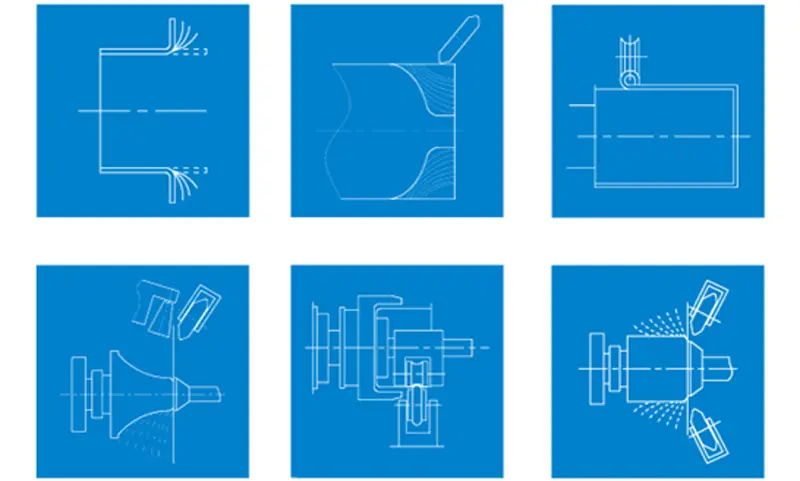

In the chip free forming process of spinning, the first step is to rotate the metal disc blank, billet or preform. Squeezing metal parts through spinning wheels and causing the metal to start flowing. By using this method, complex busbar shapes can be obtained with extremely low tool costs. Various hollow bodies with extremely small tolerance range and excellent surface quality. The advantages of the spinning process are obvious: using this process, the wall thickness and contour of the workpiece can be accurately determined to the greatest extent possible, and the wall thickness and contour can be accurately repeated.

01

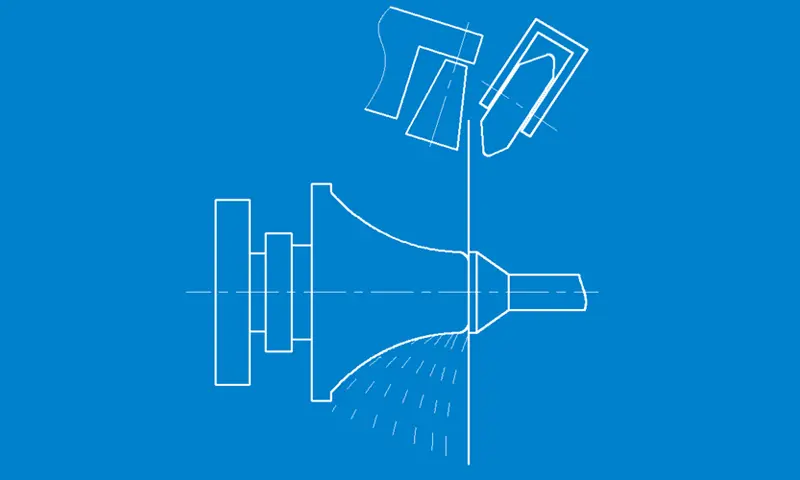

Deep drawing spinning is a forming process that mainly uses radial deep drawing to reduce the diameter of the blank (sheet or preform). It can also be said that it is similar to deep drawing, but uses a core die instead of a punch, and a rotary wheel instead of a die. It is the most important and widely used forming method in spinning. The bending plastic deformation of the blank is its main deformation method.

Due to the fact that the workpiece is rotated by the motion of the spinning wheel, it has greater degrees of freedom in processing conditions compared to deep drawing, and can produce very complex rotational symmetries. During the spinning process, there are high requirements for the motion trajectory of the spinning wheel. Therefore, it is highly necessary to describe the forming technology of deep drawing and spinning as mastering the laws of the spinning wheel movement.

01

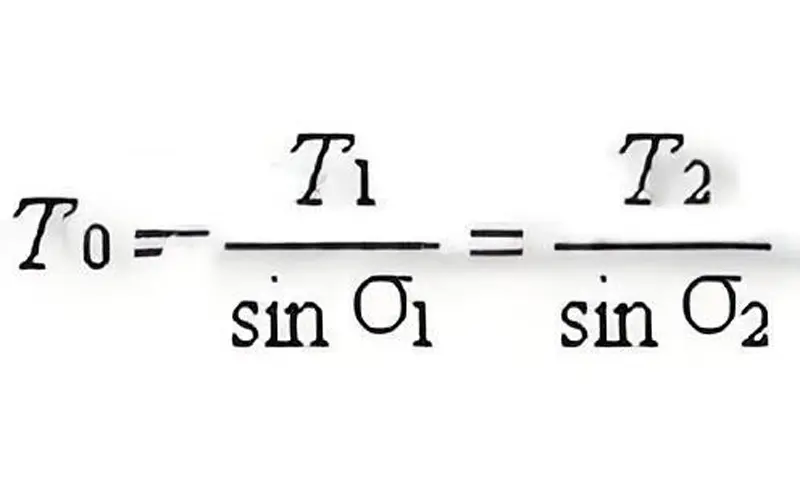

Shear spinning refers to the spinning method of manufacturing various axisymmetric thin-walled parts such as cones by changing the thickness of the blank without changing its outer diameter (cone thinning spinning). The characteristics of this forming method are that the spinning wheel is subjected to less force, the half cone angle and wall thickness affect each other, the material flows smoothly, the surface is smooth and the forming accuracy is high, and it can easily form materials that are difficult to form by deep drawing spinning. The theoretical calculation formula followed during the spinning process is:

According to the comparison between the actual wall thickness T11 of the workpiece after spinning and the theoretical value T1, there are two spinning methods: over spinning (T11>T1) and under spinning (T11<T1).

01

Flanging and curling

According to the shape and size of the formed part, the method of using a rotary wheel to unscrew the flange at the pipe end is called flanging forming. Flanges are divided into outer flanges and inner flanges. The rotary wheel used is generally a combination of circular arc and cylindrical flanged wheels. When spinning, first push the workpiece edge through the circular arc segment to flip it into an arc shape, and then use the cylindrical segment to apply film and flatten it into a flange shaped flange.

Rolling edge forming is the process of rounding the end of a spun part to enhance its rigidity, and sometimes it can also be used as a decoration to beautify the appearance of the workpiece. Curling is formed by using a curling wheel with an outer circular arc groove to push and press the edge of the spun part. Depending on the shape of the curled edges, corresponding wheels can be used for processing.

Generally, it is required that the rolled edges have a certain degree of sealing, good anti leakage performance, and impact resistance, so as to ensure that the steel drum can withstand various forms of collisions and drops during transportation and storage. During the edge rolling process of the flanging machine, the steel drum is subjected to the rolling action of the flanging machine, which forcibly curls the barrel body and the top and bottom of the barrel, achieving a tight bite. In order to curl and deform the barrel body and top and bottom during rolling, the flanging machine gradually reduces the deformation resistance as much as possible.

During the spinning process, not only does it change the shape of the blank, but it also significantly reduces its wall thickness, which is called strong spinning (also known as thinning spinning).

A short and thick cylindrical blank is fitted onto a core rod, and during rotation, a large external force is applied through the movement of the rotating wheel to a very small area, causing plastic deformation. Due to the high flow resistance of the metal being spun, it flows along the axis with the least resistance and accumulates into a thin-walled long tube, hence it is called tube thinning spinning.

01

Narrowing spinning

Using spinning tools to perform radial local spinning compression on hollow parts or tubular blanks of rotating bodies to reduce their direct forming method.

The shrinking process is to clamp the blank concentric in an appropriate core mold (solid core, combined or coreless mold), exposing the part that needs to be formed outside the fixture. When the spindle drives the blank to rotate, according to the control method used, the rotary wheel moves back and forth according to the specified shape trajectory, gradually reducing the diameter of the blank and obtaining a part with a waist drum shape or a closed spherical shape.

In order to avoid wrinkling and cracking of the workpiece during shrinking, the process is divided into several passes or processes based on the ratio of the diameter before and after forming. That is, the rotary wheel needs to make multiple reciprocating movements, and the feed rate for each pass is determined based on the diameter reduction ratio. For the specific situation of forming parts with different shapes and materials, sometimes it is necessary to replace the core mold several times and perform intermediate heat treatment. If necessary, it should be rotated under heating conditions.

There are usually three situations of wall thickness in the reduced diameter area of the workpiece: constant wall thickness, thinning wall thickness, and increasing wall thickness.

The variation of wall thickness is mainly related to the degree of diameter reduction and material properties. When the open end of a hollow workpiece is subjected to contraction and rotation, the above three situations may also occur.

Different production methods can be adopted based on the shape, material, and quality requirements of the workpiece.