How to Judge the Quality of Spinning Products?

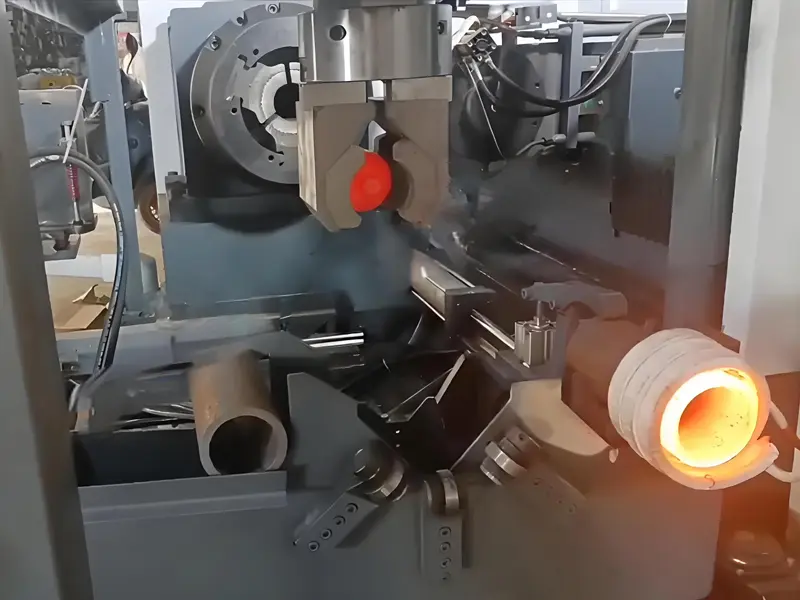

Cnc Spinning is a metal processing method that has gradually entered people's field of vision in recent years. Compared with common hardware processing processes such as turning, milling, and stamping, it is very different. Due to the lack of understanding of CNC spinning technology, many customers do not know from what perspective to judge the quality of CNC spinning products. The following is a detailed introduction from several aspects.

Ⅰ. Diameter accuracy of spinning products

In terms of product diameter accuracy, the accuracy of CNC spinning products cannot reach the processing accuracy of CNC turning or milling. The processing accuracy of turning and milling can generally reach 0.02mm. However, due to the combined influence of factors such as material thinning, material stress rebound, and clamping accuracy, the accuracy of spinning cannot reach the accuracy level of turning and milling. Generally, the forming diameter accuracy of stainless steel is 0.3mm-1mm, and the forming accuracy of aluminum is 0.5-1.5mm.

Ⅱ. Length accuracy of spinning products

Since spinning processing hardly involves cutting process, most of the time, the length accuracy of spinning products is controlled by turning processing. Considering the rebound of stress after partial cutting of the material, the length accuracy of general spinning products can reach 0.1mm.

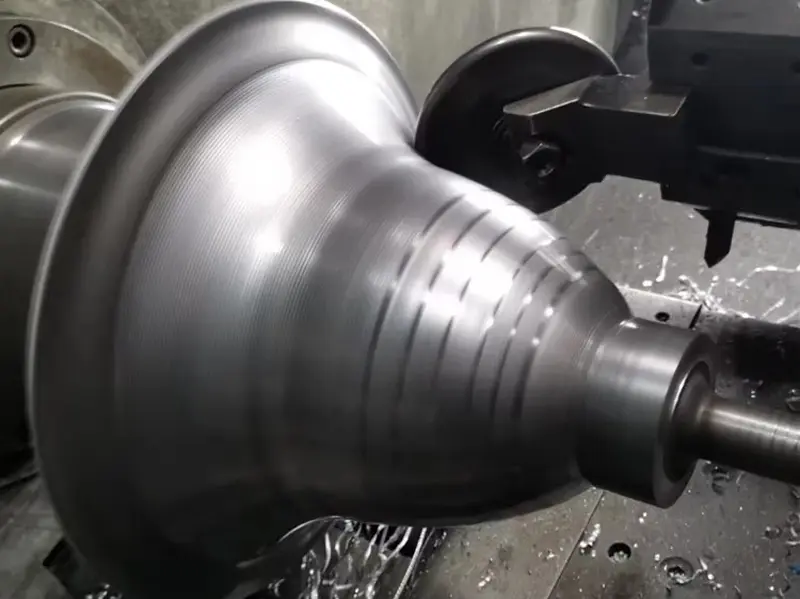

Ⅲ. Spinning texture of spun products

Generally, spun products will have slight textures. The distribution of surface textures is related to the spinning tool path and the size of the selected knife wheel. However, if the product has local depressions or protrusions, it is due to the process not being properly debugged. If the product needs to be polished, oxidized, or painted later, aluminum spun products can use a calendering knife to process the surface texture of the spinning. Stainless steel spun products can improve the process to make the texture distribution more uniform and fine, so as to reduce the cost of polishing.

Ⅳ. Spinning product wall thickness

The distribution of product wall thickness will affect the performance of the product material in terms of strength. In addition to using different material thicknesses to control product wall thickness, product thickness can also be controlled by improving the process. For high-quality spinning products, the wall thickness of the product is very uniform everywhere.

It should be noted that the quality judgment of spinning products needs to take into account the shape, material differences and the proficiency of technicians. The specific requirements vary from product to product and cannot be generalized.