0102030405

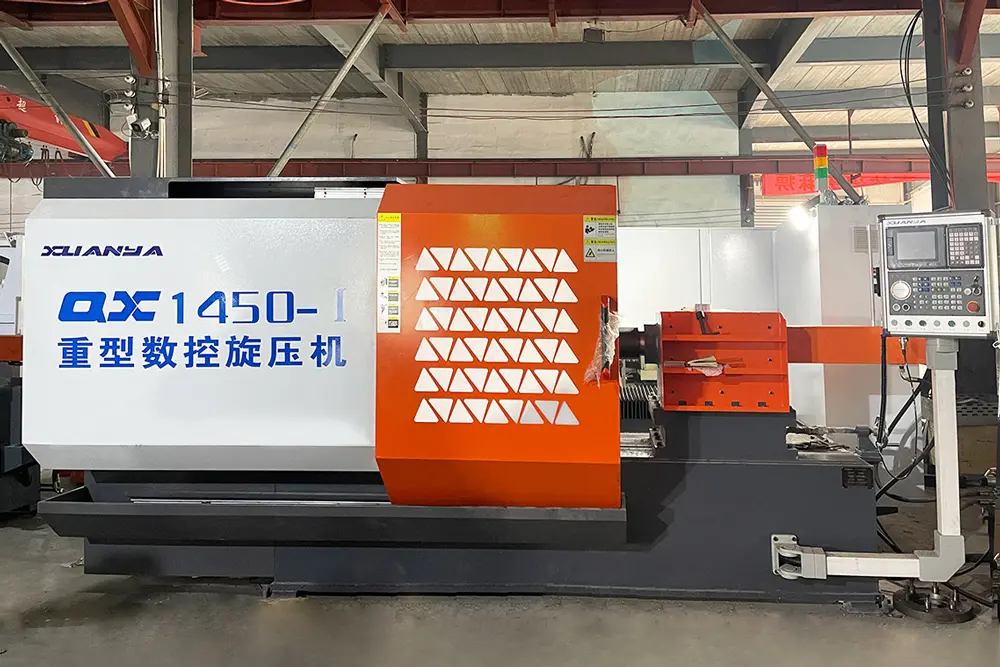

High-Precision CNC Plate Spinning Machine For Fan Cookware Hardware Kitchenware

Product Description

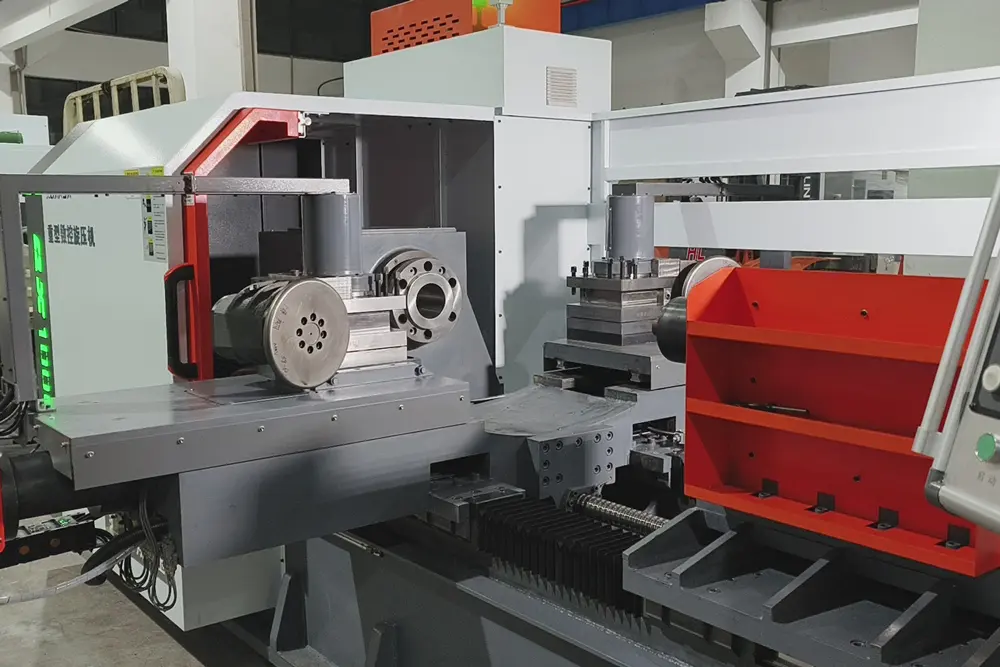

The advantages of the CNC spinning machine is its broad adaptability, allowing it to be utilized in numerous fields. These include electronics, home appliances, automotive manufacturing, precision instruments, and cultural supplies. This versatility ensures that manufacturers can rely on the PX450 for a multitude of production needs, enhancing operational efficiency and reducing the need for multiple machines.

The incorporation of advanced CNC technology into the PX450 allows for precise control throughout the entire processing cycle. This technology ensures that the accuracy and consistency of each part produced are maintained at the highest standards. Operators can utilize the CNC system to set specific processing parameters, including pressure, speed, and feed rate, which are crucial for achieving optimal results. This level of control not only refines the spinning process but also enables the machine to adapt seamlessly to the intricate requirements of various complex part shapes.

In summary, the PX450 CNC spinning machine stands out as a powerful and efficient solution for manufacturers seeking to produce high-quality components with intricate designs. Its maximum processing diameter of 450mm, combined with its ability to handle a wide range of materials and shapes, positions it as a key asset in modern manufacturing environments. The advanced CNC technology further enhances its capabilities, ensuring that each part meets the precise specifications required by today's demanding industries.

Product parameters

|

Item |

Parameter |

|

|

Model |

PX-450Ⅰ |

|

|

Maximum sheet diameter |

450mm |

|

|

Diameter of over-drag plate |

300mm |

|

|

Main motor power |

7.5kw |

|

|

Spindle speed |

3000Rpm |

|

|

Stroke |

X-axis |

500mm |

|

Z-axis |

550mm |

|

|

Maximum tail force |

7kn |

|

|

Tail stroke |

300mm |

|

|

Processing material thickness |

Copper/aluminum |

0.5-3.0mm |

|

Steel |

0.5-2.0mm |

|

|

Stainless steel |

0.5-1.5mm |

|

|

Tool holder station |

4+1 |

|

|

Whip blank support plate travel |

300mm |

|

|

Positioning accuracy |

0.01mm |

|