0102030405

CNC Metal Tube End Thinning Heat Spinning Lathe Machine For Cookware Kitchen Pot

Product Description

-

-

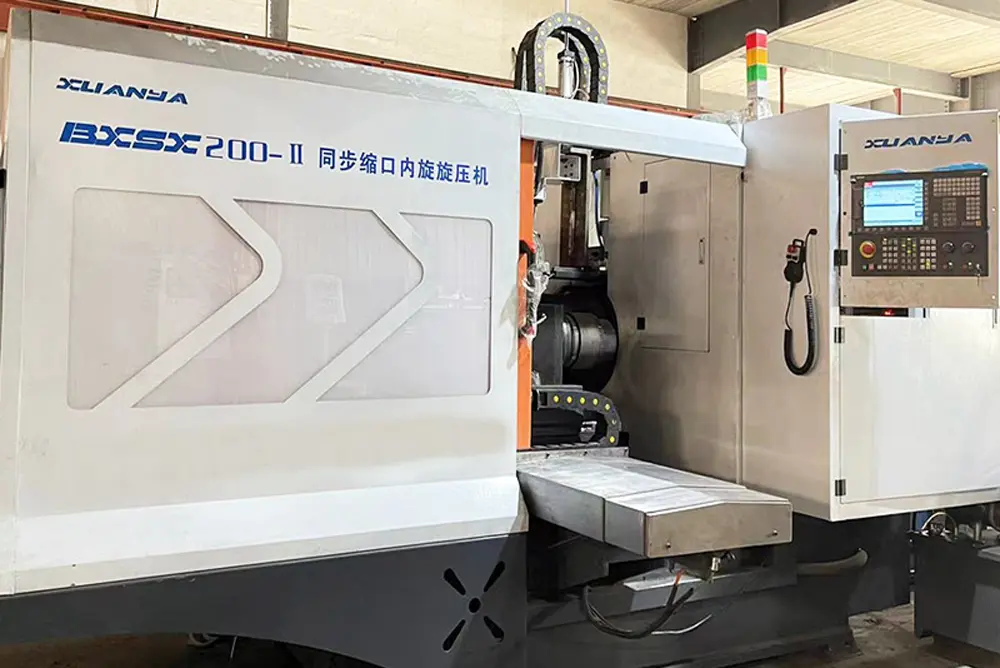

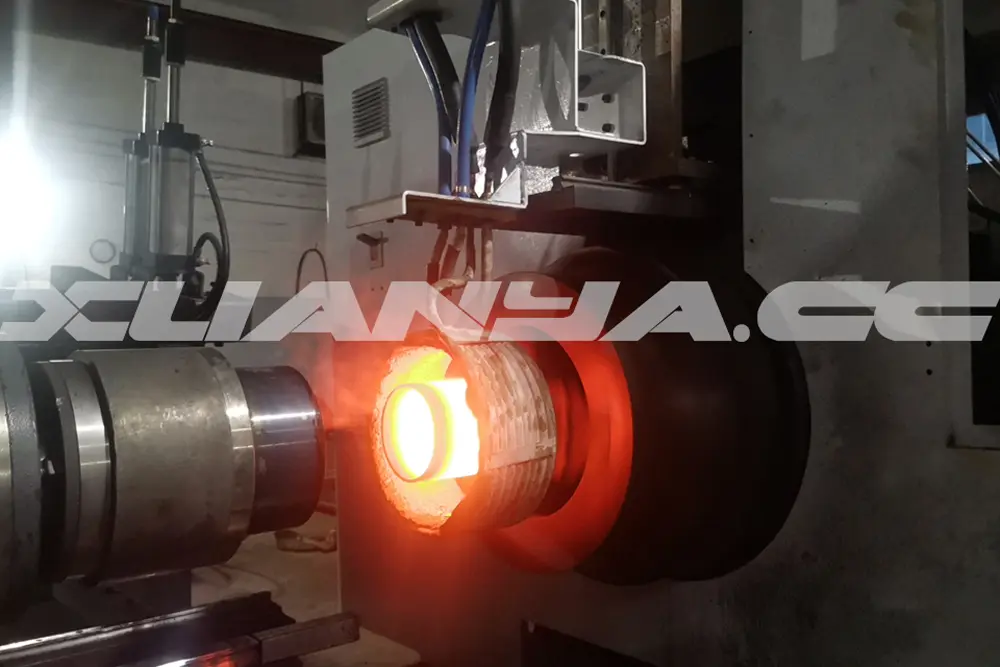

The emergence of double-wheel shrink spinning machines effectively solves the technical bottlenecks in traditional forging, cold extrusion, stretching and other processes, especially the limitations in feature forming. Traditional processes often require complex mold design and high mold costs, while double-wheel shrink spinning machines greatly reduce mold costs and shorten product development cycles. This advantage enables many companies to be more efficient and respond quickly to market demand during the development of new products.In addition, the application field of the double-wheel shrink spinning machine is very wide. In addition to its application in the pipeline manufacturing industry, it can also be used in many fields such as automobiles, aerospace, and machinery manufacturing. In the automotive industry, it can be used to manufacture lightweight body structural parts; in the aerospace field, it can process high-strength aviation components; in machinery manufacturing, it can realize the processing of parts with complex shapes. In short, the double-wheel shrink spinning machine is promoting technological progress and product innovation in many industries with its high efficiency and flexibility.

Product parameters

|

Item |

Parameter |

||

|

Model |

SX-100 |

SX-150 |

SX-200 |

|

Control System |

CNC |

||

|

Motor |

Digital AC Servo Motor |

||

|

Maximum blank diameter |

100 mm |

150 mm |

200 mm |

|

Spindle speed change |

Servo stepless speed change |

||

|

X/Z axis pulse equivalent |

0.001mm |

||

|

Positioning accuracy |

0.01mm |

||

|

Repeatability |

0.02 mm |

||

|

Thickness (Stainless Steel) |

0.8-2mm |

1-3mm |

2-4mm |

|

Spinning lubrication |

Automatic spray lubrication |

||

|

Stroke protection |

Have |

||

|

Number of spindle gears |

Infinitely variable speed |

||

|

Hand wheel |

Have |

||

|

Machine tool lubrication |

Centralized automatic refueling |

||