0102030405

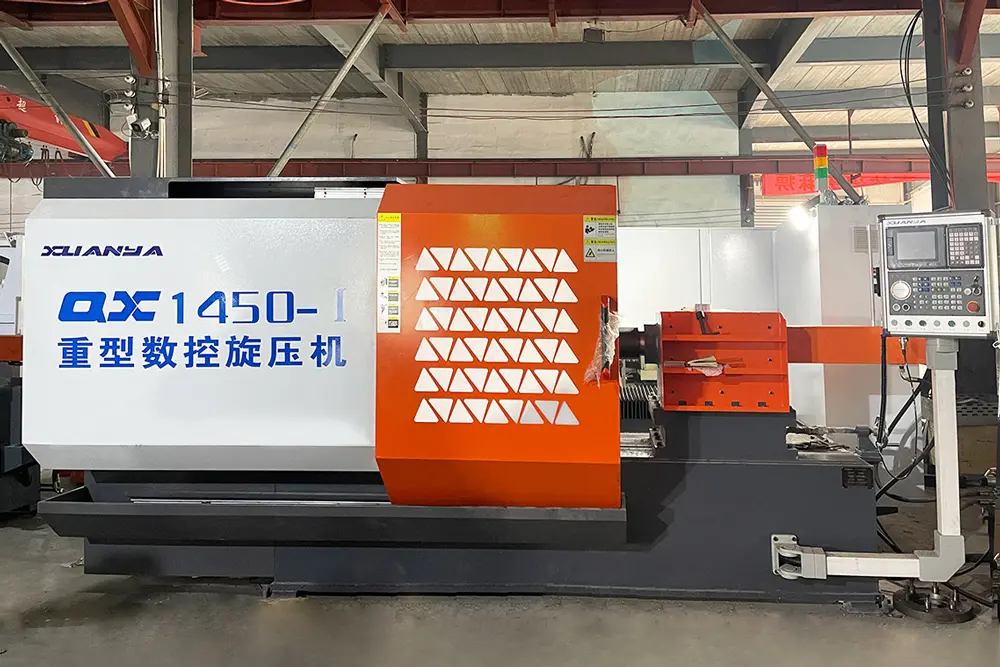

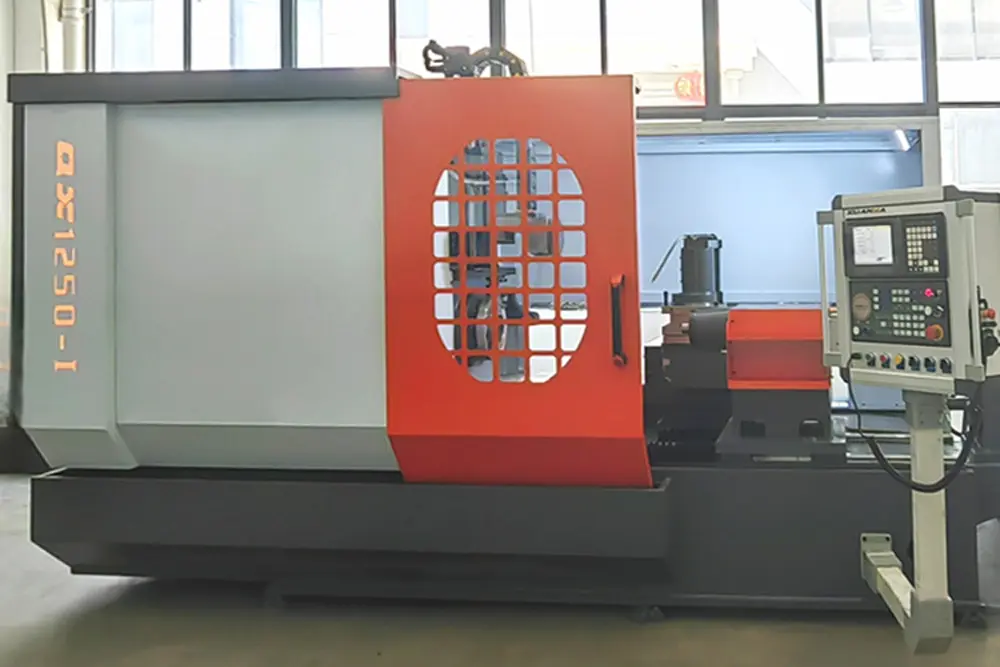

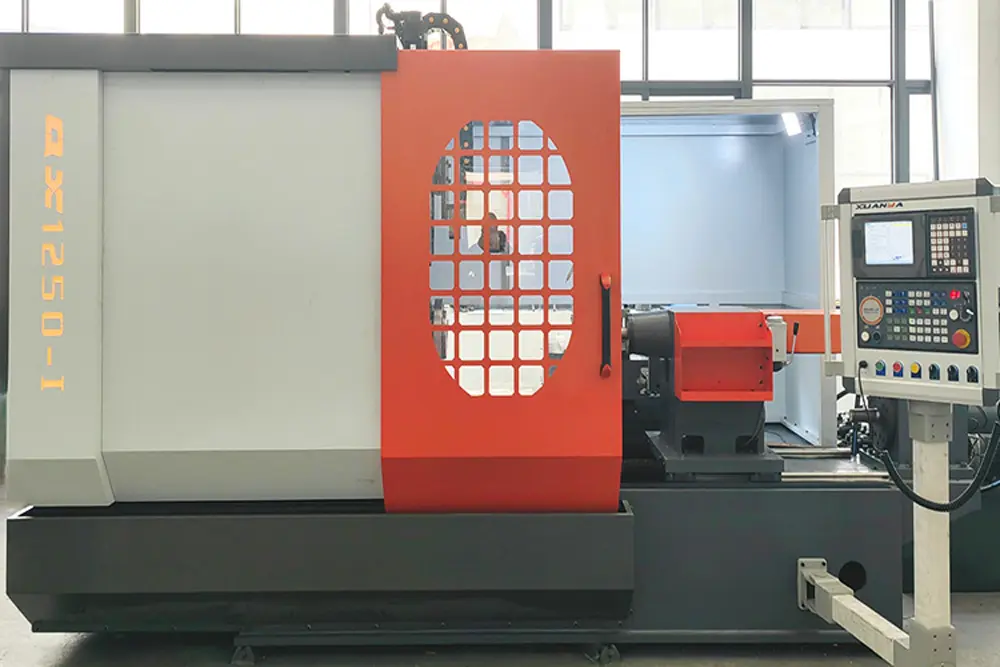

Advanced CNC Metal Plate Spinning Machine For Precision Metal Pipes, Cylinders And Conical Parts

Product Description

The primary advantages of the PX-1250 and QX-1250 CNC spinning machines is their capability to achieve precise arc transitions, which is essential for creating high-quality and consistent products. These machines are designed to optimize material usage by minimizing waste, making them both cost-effective and environmentally friendly. By reducing material waste, they significantly enhance production efficiency and lower overall production costs, contributing to a more sustainable manufacturing process—an increasingly important factor in today’s competitive industrial landscape.

In addition to their remarkable precision, these machines also prioritize workplace safety. Their stable and reliable operation helps to mitigate the risk of accidents, fostering a safer working environment. Furthermore, the enhanced functionality of the PX-1250 and QX-1250 allows for the automation of many strenuous and repetitive tasks, which reduces operator fatigue and the likelihood of human error.

These machines are particularly well-suited for industries that require high-quality precision metal forming, such as aerospace, automotive, and kitchenware manufacturing. These sectors demand tight tolerances, smooth finishes, and consistent product quality. With their dependable operation, minimal downtime, and capability to handle complex geometries, the PX-1250 and QX-1250 CNC spinning machines provide a valuable solution for manufacturers aiming to produce high-precision, cost-effective products while ensuring a high level of safety and efficiency in the workplace.

Product parameters

|

Item |

Parameter |

|||

|

Model |

PX1250-Ⅰ |

QX1250-Ⅰ |

QX1250-Ⅱ |

|

|

Maximum sheet diameter |

1250mm |

1200mm |

1250mm |

|

|

Diameter of over-drag plate |

800mm |

|||

|

Main motor power |

30kw |

|||

|

Spindle speed |

1000Rpm |

|||

|

Stroke |

X-axis |

1250mm |

1200mm |

1200mm |

|

Z-axis |

800mm |

|||

|

Maximum tail force |

15kn |

20kn |

20kn |

|

|

Tail stroke |

500mm |

|||

|

Processing material thickness |

Copper/aluminum |

0.5-5.0mm |

0.5-5.0mm |

0.5-8.0mm |

|

Steel |

0.5-4.0mm |

0.5-4.0mm |

0.5-5.0mm |

|

|

Stainless steel |

0.5-2.5mm |

0.5-2.5mm |

0.5-4.0mm |

|

|

Tool holder station |

4/8 |

4/6/8 |

1+1/4+4 |

|

|

Whip blank support plate travel |

300mm |

|||

|

Positioning accuracy |

0.02mm |

|||